Proceedings

of the 9th International Conference on Recirculating Aquaculture; Roanoke, VA; 08/24/2012, pp. 76-78.

William A. Wurts, Senior State Specialist for Aquaculture

Kentucky State University CEP

P.O. Box 469, UKREC, 1205 Hopkinsville Street, Princeton, KY 42445, USA

In late 2006 and early 2007,

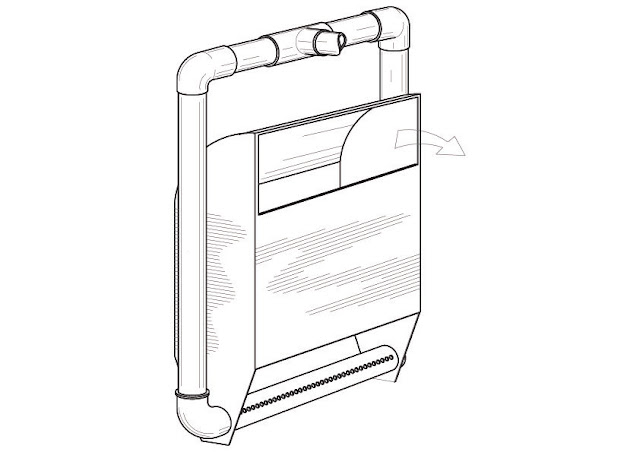

Pond test of the Wurts-Herron rectangular airlift prototype in April 2007.

Side view of single and dual-cylinder air injector configurations.

References

Reinemann, D.J. and M.B. Timmons. 1988. Airpump version 1.0. Airlift Pumping and Aeration Design Program. Cornell University Agricultural Engineering Department, Ithaca, NY.

Wurts, W.A. and R.G. Herrron. 2008. Airlift pump. Provisional patent, USPTO 61/072,198.

Wurts, W.A. and R.G. Herrron. 2009. Airlift pump. Non-provisional patent application, USPTO 12/383,779 (publication suppressed).

No comments:

Post a Comment